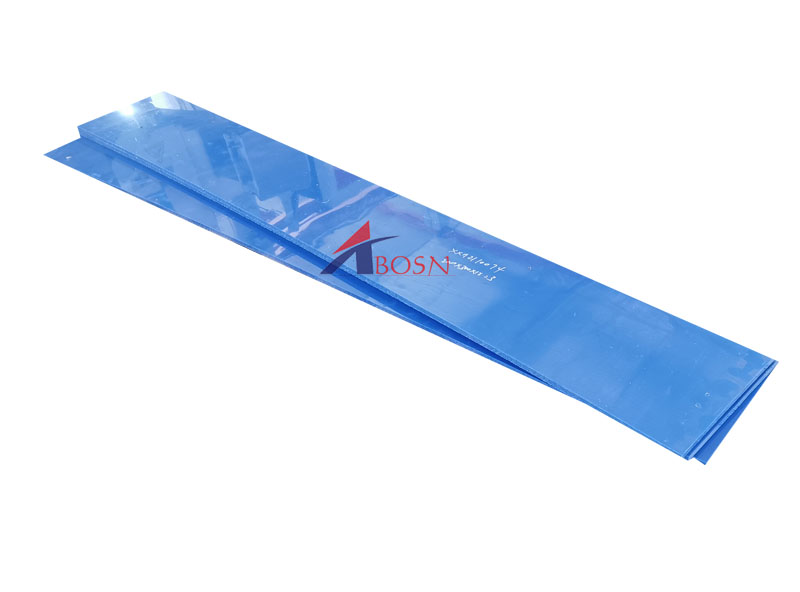

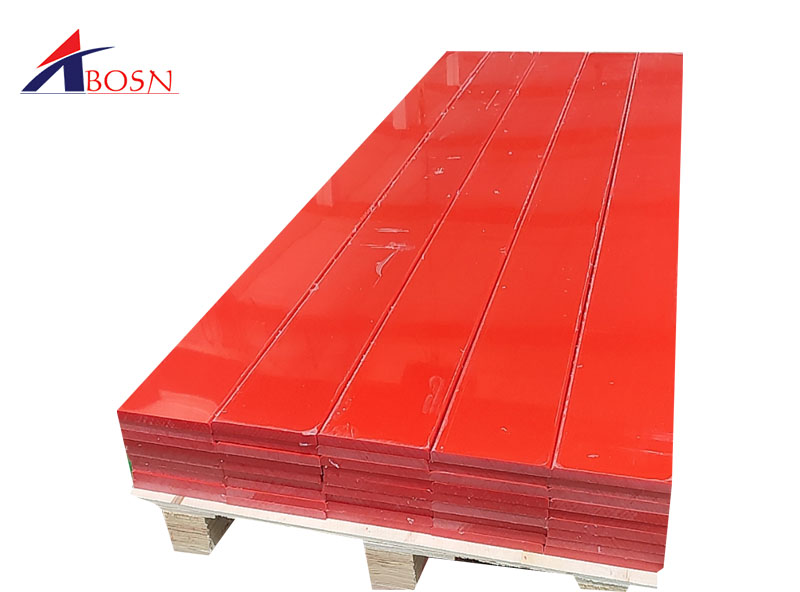

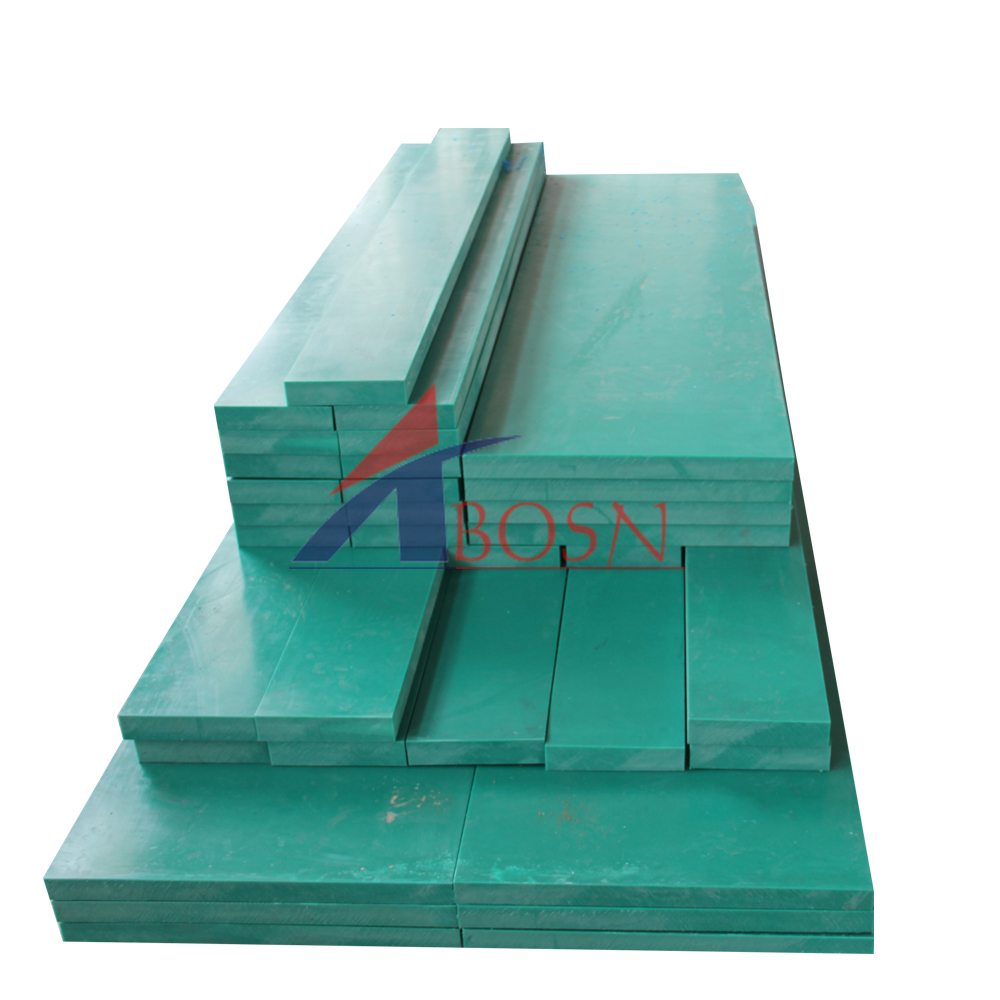

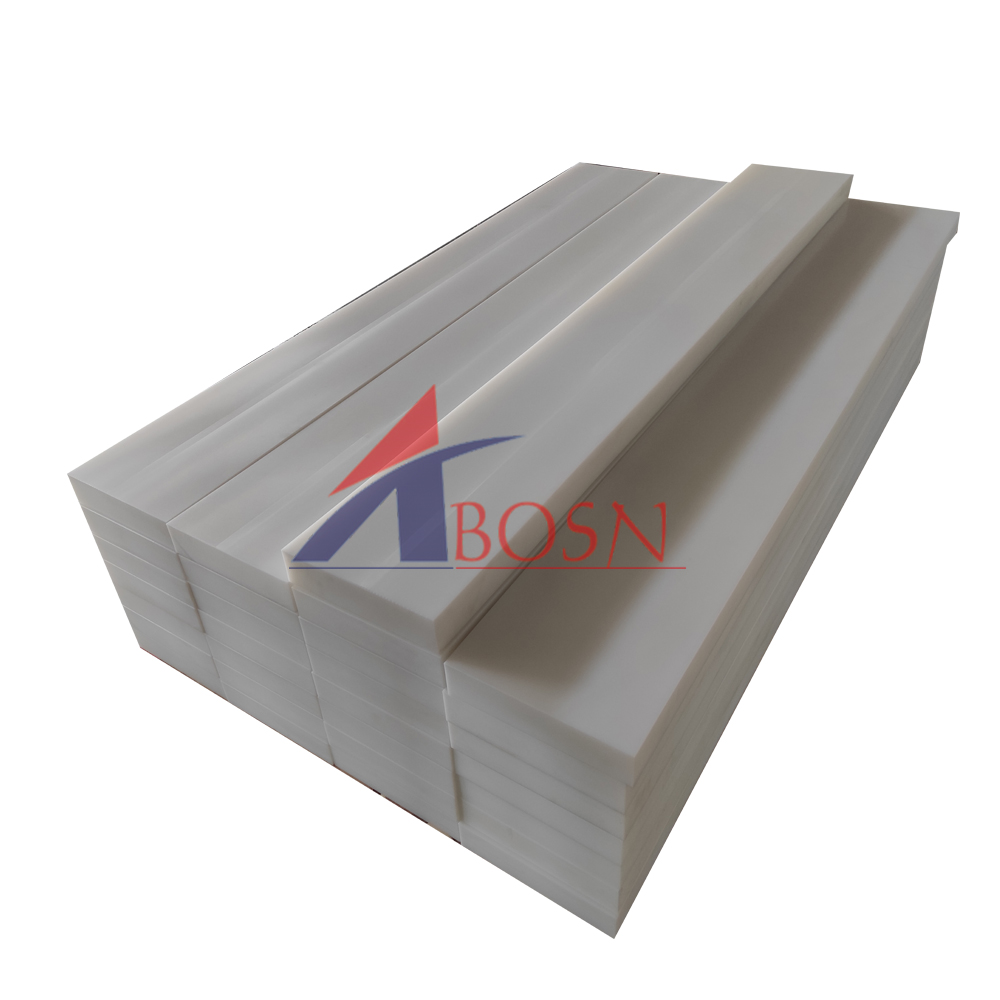

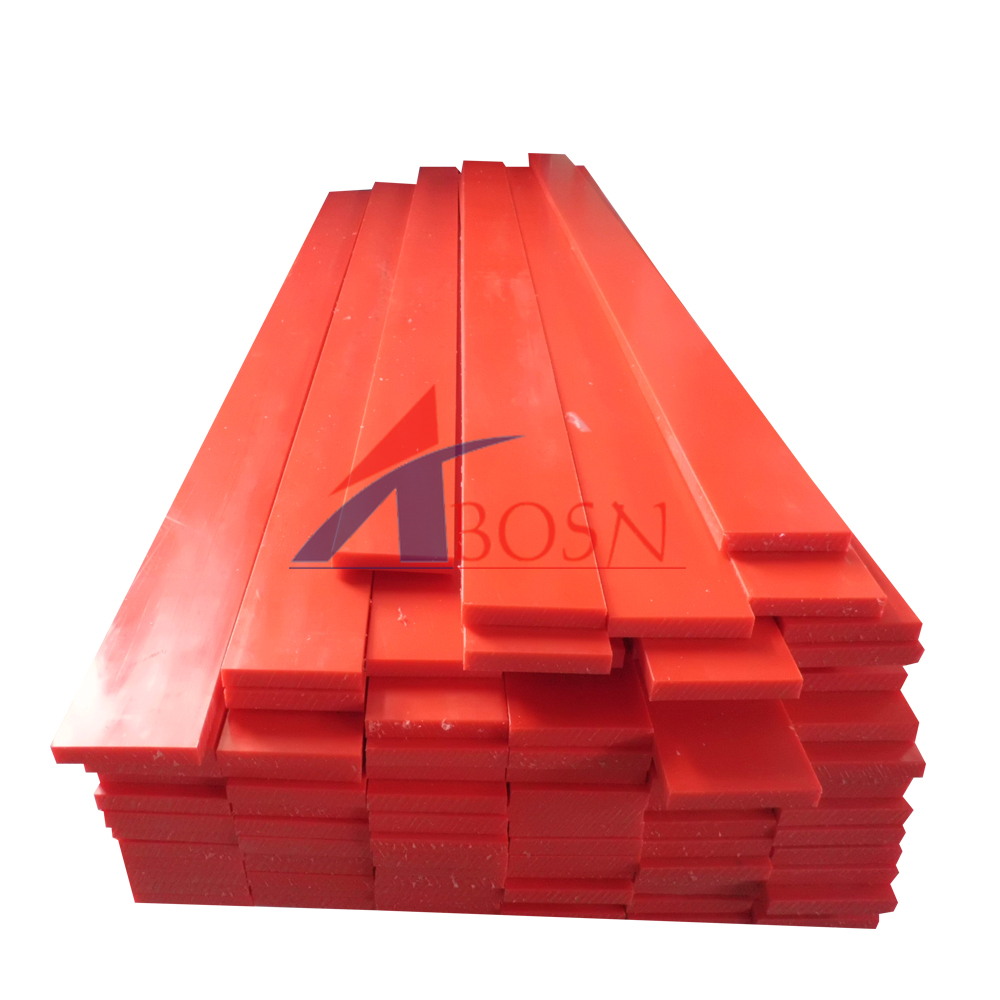

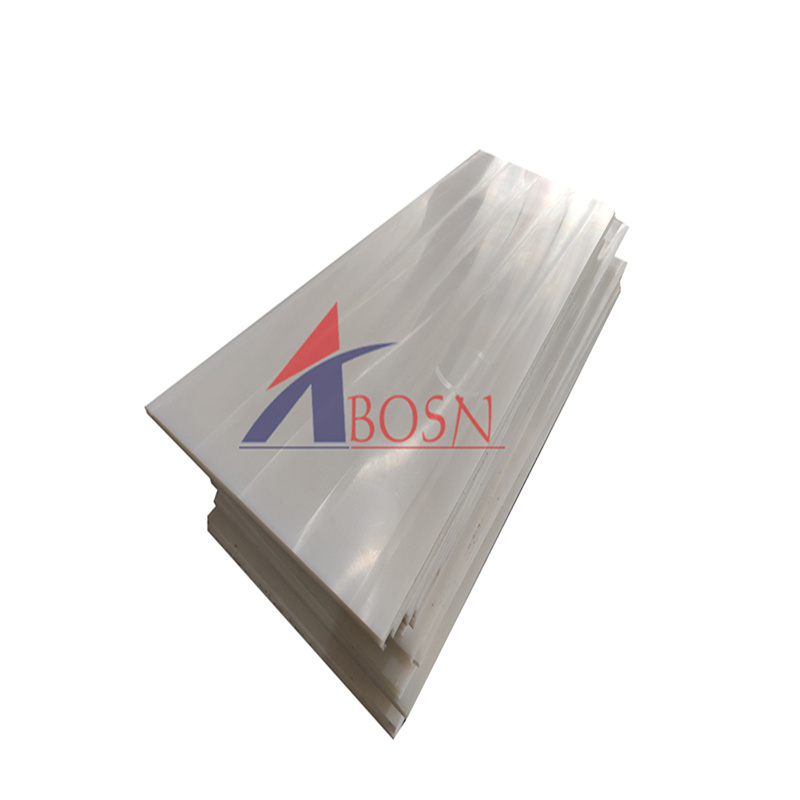

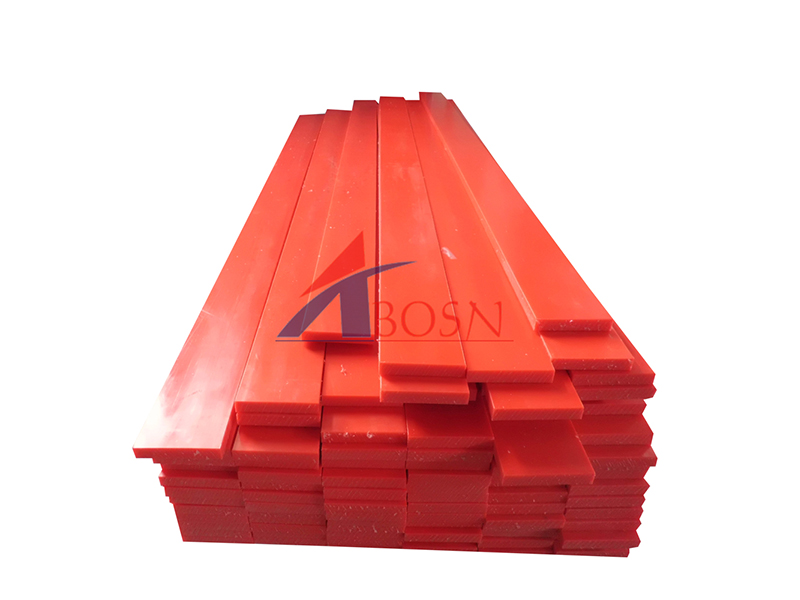

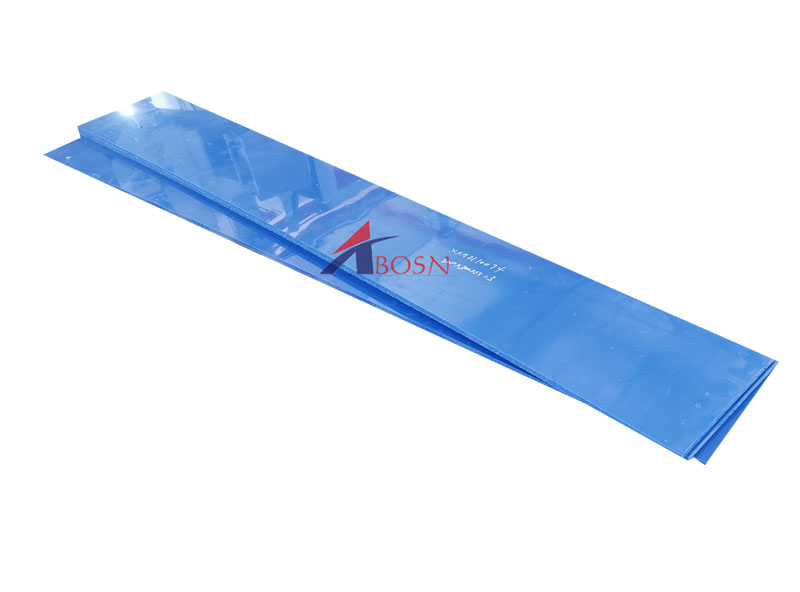

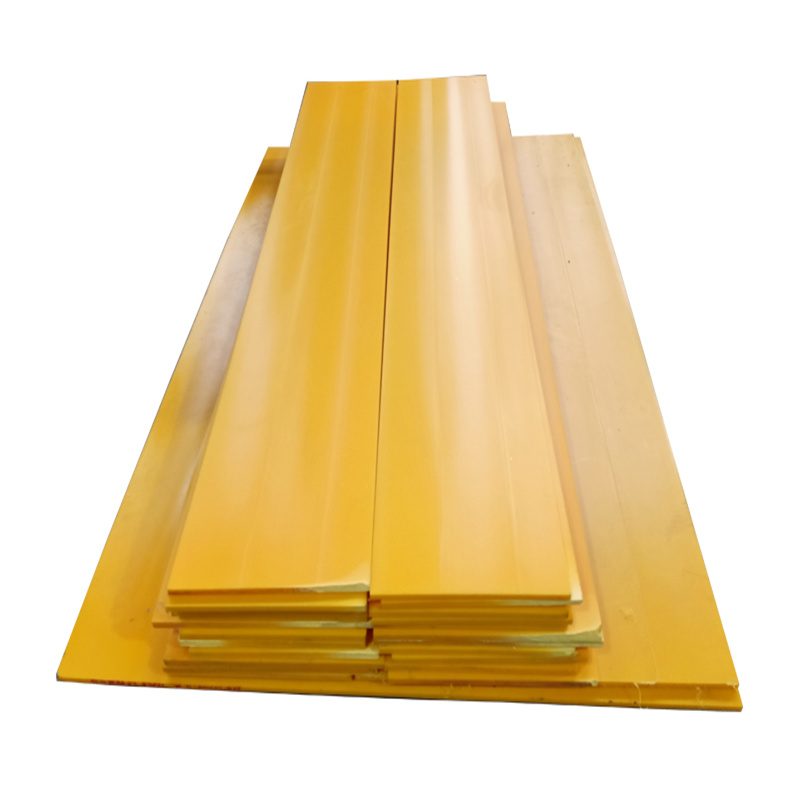

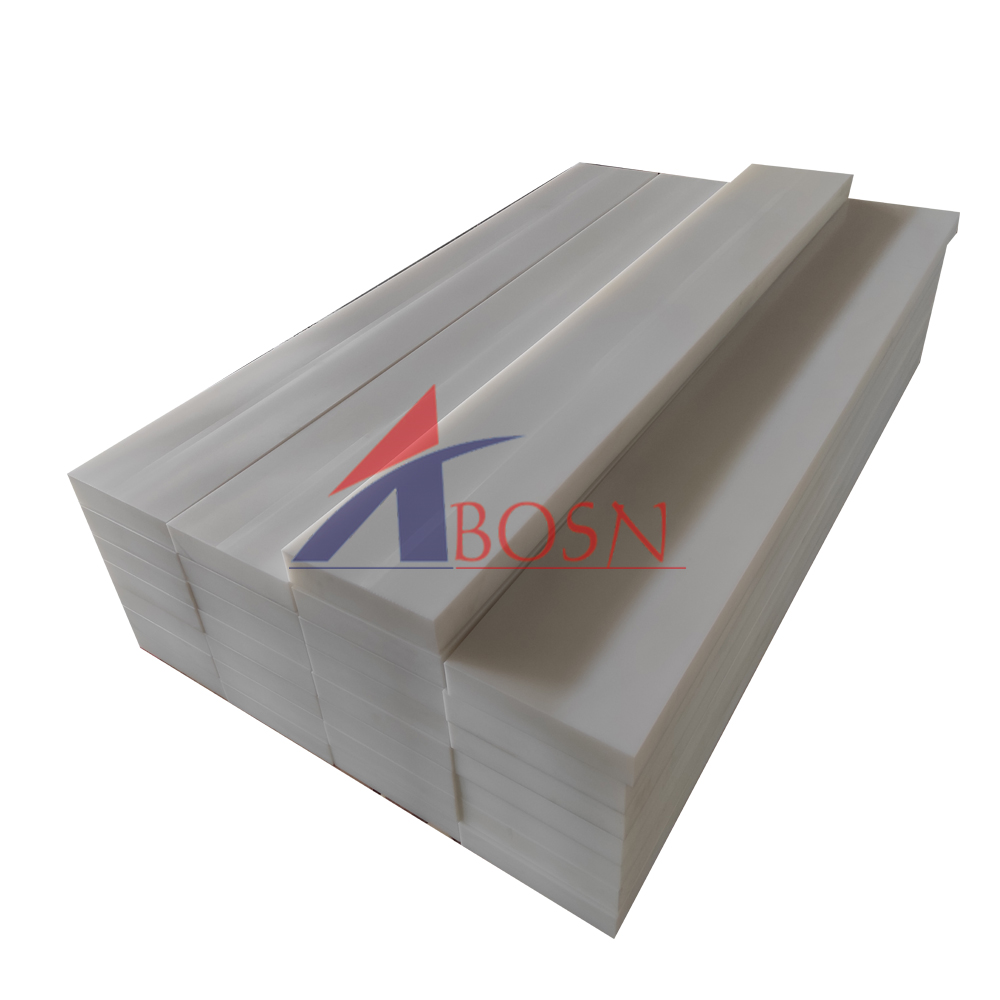

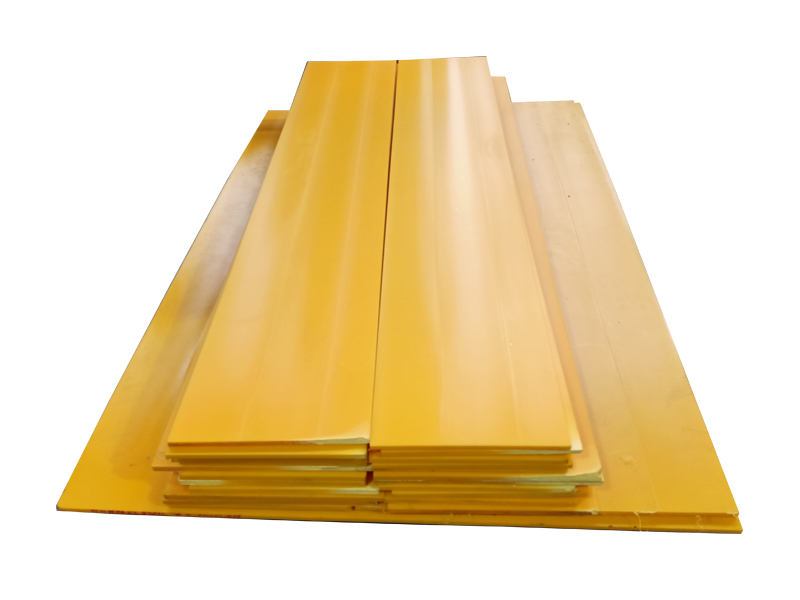

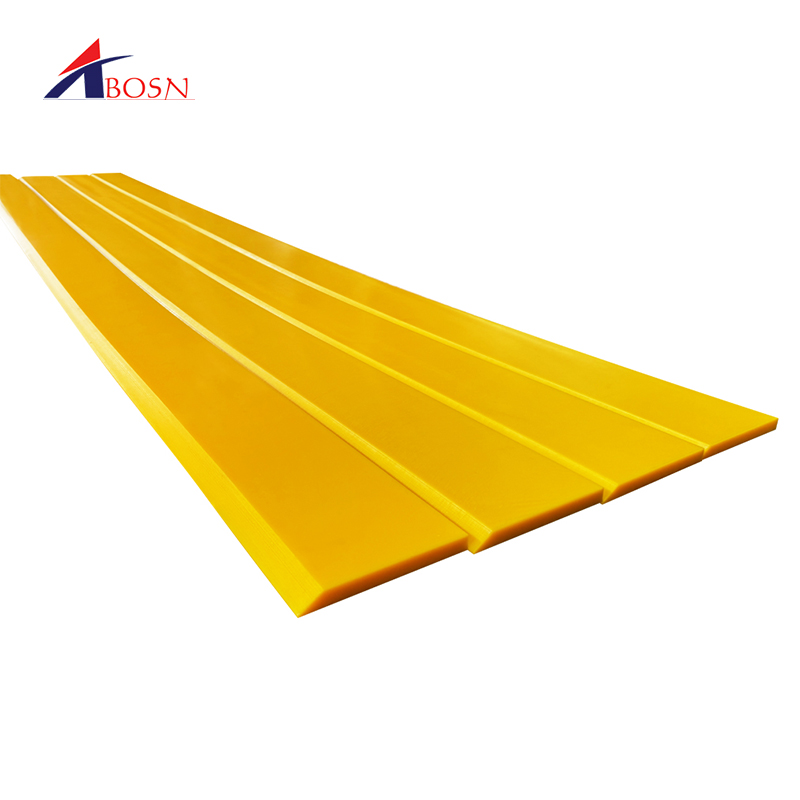

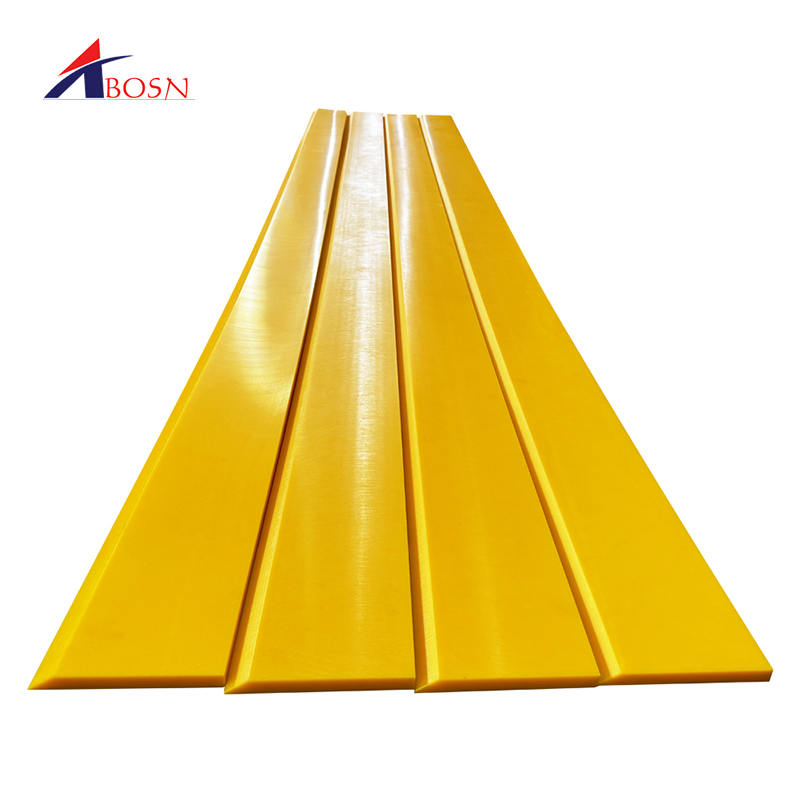

Custom UHMWPE Conveyor Wear Strips UHMWPE Plastic Wear Strips UHMWPE HDPE Conveyor Wear Strips

Color: white and black routine, any other standard colors can be produced according to customer demand.

Size: 8- 300mm thickness .

Length and width has no limitation.

Accurate drawings in accordance with the specific needs of customers to process.

Material :HMWPE500,UHMWPE 1000,UHMWPE 2000

Besides HDPE block is also available with us .

Features of UHMW Wear Strips

High Wear Resistance: UHMW-PE has good wear resistance and is attracting attention in all current engineering plastics.

For example, UHMW-PE pipes have a long service life under strong corrosion and high wear conditions, and improve delivery efficiency.

It fully demonstrates the superiority of “energy saving, environmental protection, economy,”.

2. Corrosion Resistance: in the lye is not stable in some nitric acid, it is stable to seawater, liquid detergent.

3. Very Low Friction Coefficient: static friction coefficient of 0.07, good self-lubricating, is an ideal bearing, bushing, slider, lining material.

UHMW-PE is selected as the friction component of the equipment, in addition to improving the wear life, it can also receive energy-saving effects.

4. Impact Resistance: impact resistance in plastic Whether it is strong external impact, or internal pressure fluctuations, it is difficult to crack.

Especially in low temperature environments, the impact strength is high, and its flexibility provides an extremely reliable guarantee for the conveyor system.

5. Anti-aging: stable performance, good aging resistance, ground and underground can be buried, 50 years without aging.

6. Electrical Performance: large volume resistance. Suitable for use as a structural material for electrical engineering over a wide range of temperatures and frequencies.

7. Hygienic and Non-toxic: UHMW-PE is tasteless, non-toxic, odorless, non-corrosive, physiologically inert and physiologically adaptable.

8. When the molecular weight of the polymer polyethylene liner exceeds 1.5 million, the embrittlement temperature drops to -140 °C. Below -180 ° C,

there is still a certain mechanical strength.

9. Water Resistance UHMWPE water absorption is very low, generally less than 0.01, almost no water absorption, no deformation in water does not deteriorate.

10. Light Weight: UHMWPE has a density of 0.93-.97. It is a medium-density material with many materials and light weight. It is easy to handle and use, and provides work efficiency.